how to measure clutch plate thickness|how to measure clutch height : distribution In this tech tip, I will teach you how to determine whether your clutch plate fibers, steel plates, and clutch springs are still in operating spec! You will need a digital caliper and. The best Virginia sports betting is always at BetRivers! LEARN MORE. We Proudly Accept: Active Loyalty Level: Loyalty Points: Loyalty Level Points to reach next level: Loyalty Level Points expiring tonight: Virginia Sports Betting at its Best! ⭐ Claim your $250 sportsbook BONUS for NFL betting & more at our VA sportsbook ⭐.

{plog:ftitle_list}

WEBComercial x XV de Piracicaba, 07.03. XV de Piracicaba x Noroeste, 10.03. Monte Azul x XV de Piracicaba Confira os resultados da Supercopa do Brasil 2024 ao vivo em Flashscore.com.br: 04.02. Palmeiras x São Paulo incluindo prévias, estatísticas de confronto direto (H2H), placares ao vivo e relatórios de partida da Supercopa do Brasil!

Some vehicles come with multiple clutch plate sizes that can be fitted from the factory. This video shows how to measure your clutch plate. Step 5: Measure the Clutch Plate Thickness. Use a caliper to measure the thickness of the clutch plate. Refer to your vehicle’s service manual for the specified thickness . The first spec is clutch disc diameter, taken by simply measuring across the face of the clutch disc. Knowing your pressure plate diameter is valuable too, and you take that . In this tech tip, I will teach you how to determine whether your clutch plate fibers, steel plates, and clutch springs are still in operating spec! You will need a digital caliper and.

The stock driving clutch plate segments usually measure .155” thick (new), but will wear thin in service, leading to clutch slipping.

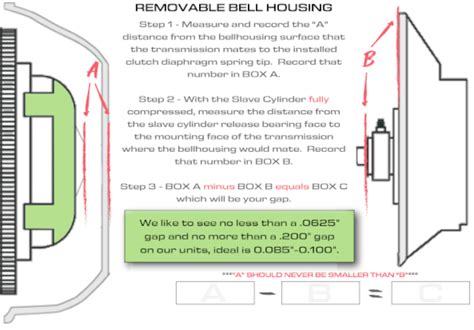

To do so, you need to take two measurements: Measurement "A" is the distance between the surface of the bell housing that meets the transmission to the tip of the pressure plate fingers. To get an accurate measurement, the clutch must .

To determine wear on the clutch plates, both the H-D and Clymer manuals say to take the (8) friction plates, wipe them off, stack them together, and with calipers, measure the .

The parts diagrams for OEM parts doesn't match the shop manual for order of the 2 different thickness steel plates. There are 2x 1.6mm thickness steel plates, and 7x 2.0mm thickness steel plates. The number of each steel . Clutch & Pressure Plate Measurements. Atlantic TC T-TEN. 519 subscribers. Subscribed. 41. 6.5K views 4 years ago. TIS gives us several specifications for the clutch disc and pressure.

Some models require more than one thickness of metal plates in the clutch pack. When inspecting the metal plates, check to make sure that they are flat and not discolored . The parts diagrams for OEM parts doesn't match the shop manual for order of the 2 different thickness steel plates. There are 2x 1.6mm thickness steel plates, and 7x 2.0mm thickness steel plates. The number of each steel .

Taking a clutch apart that is not slipping to measure the friction plates, nothing but a waste of time. Making something out of nothing. When I worked as a tech at a Honda shop all those years ago, I don't ever remember taking a clutch apart to measure the friction plates, just simply never did that ever take place. Stupid is as stupid do.

Besides, another steel plate would make the clutch stack too tight. Measure the thicknesses of the steel plates and call around to some tranny shops to see if they have some thicker plates. Or call a NAPA store to see if they can order some thicker ones. The other option is to find a thicker backing plate that can make up the difference.The stock driving clutch plate segments usually measure .155” thick (new), but will wear thin in service, leading to clutch slipping. When the thickness of the friction segments falls to .140”, it is good practice to replace the friction plates to obviate the need to compensate for the wear by overtightening the clutch springs, resulting in . How to measure clutch plates? . Not a stock basket. If it still has the judder spring in it I believe that fiber is thinner than the others. Yes measure on the pads of the fiber plates. 04 450r. . Only show this user #4

Thanks for the great tips. I think my friction plates are a little thicker than normal. I think it probably makes sense to swap out a few of the thick plates in the direct clutch with a few of the older thin plates from the forward clutch in order to increase the clearance. I probably have about .010" on the forward clutch. I need to check this. Measure the total pack (3 fibre plates and 2 steel plates). You need a very accurate gauge (as I found out to my cost!). If you get a Surflex clutch kit then it comes with 1.3, 1.4, 1.5 & 2 x 1.6mm steel plates.The clutch disc has splines in the center hole that mesh over the splines of the transmission input shaft. That rigidly connects the disc to the wheels via the transmission. The disc is pinched solidly between the flywheel and the spring-loaded pressure plate when engaged. When the clutch pedal is pressed, the clutch .

Two things you have to do. First, measure the thickness of the friction plates, confirm if there are within service limits. Secondly, measure the the clutch spring free length, confirm they are within limits. In some instances, the steel plates get warped (very rare) and they get checks on a machinist flat with a feeler gauge. Size matters when choosing the right clutch for your application. A larger diameter clutch is going to give you better holding power. . These packages include a steel flywheel and feature a 12 inch pressure plate and disc, which gives you a nice increase in clamp load yet easy pedal effort. The mass of this unit is going to allow a driver to .In this video I detail how to measure a motorcycle clutch thickness. The clutch and specs are for a 1981 Seca 750 but the procedure is the same for most mult.with a steel plate. See figure #1. Clutch Pack Clearance: Measure the intermediate clutch clearance using Depth-Micrometer D8OP-4201-A and Gauge Bar T8OL-77003-A or equivalent. Set the gauge bar across the pump case mounting surface. The depth at the intermediate clutch separator plate should be 41.5 / 41.8mm (1.634” / 1.636”).

This is something I worry about. I have 140K on the OE clutch and have spent more than a few nights at the dragstrip and a lot of track time. Mostly I am pretty easy on the clutch, but there is no way to tell if it has 10% life left or 50%. It is not uncommon in this car for a pivot ball to break rendering the clutch useless in an instant.Stack-up is the same as OE, with alternating friction and steel plates. To insure correct clutch pack clearance when using the Anti-Drag® Steel Separators, first assemble the clutch packing using conventional steel plates of the same thickness as the Anti-Drag® Steel Plates. Apply the clutch several times and then measure clutch pack clearance. I'm finally getting back to my clutch issues and need to know the friction plate thickness for the '79 Sporty. My manual is only giving me '84 to '90 (0.150" new) specs. Mine measure only .102". Steel plates are around 0.045". Also doesn't list clutch spring free length for the two springs. . I made sure it was seated outward as much as possible then measure with the depth mic from the top of the drum down to the ring. Then I took the thickness of the snap ring and hub. Doing some math I came up with a clearance (Top of drum to clutch plate = distance to snap ring from drum top + snap ring thickness + hub thickness + clearance)

AOD end play & intermed clutch tool thickness. . All the manuals refer to it for measuring the intermed clutch clearance and give a dimension which includes the thickness . I now just feel the edge of the case where the clutches/steels rest. You want about .010 per clutch plate.so about .030-.040 total on the intermediates.Preparing the Clutch Pack 1. Measure the clutch pack thickness. a. Stack all Rekluse friction and drive plates together and measure the total thickness. b. Refer to the ring Setting Chart on the Setup Sheet and note which setting to use when installing the ring. 2. Soak the friction disks in new oil for at least 5 minutes.

A gauge is a unit of measurement used to measure the thickness of a flat sheet of metal. The gauge chart—a handy chart for converting gauges to other units of measurement—generally runs from 0 to 38, though it varies depending on the kind of metal used. . Using the measurement charts above, you can get the correct plate thickness every .

2-6 Clutch Clearance Measurement - WITHOUT Factory Tools Figure 367 Figure 368 Figure 369 Figure 370 41. Adjust the “H” Gauge measuring rod so it just touches the ledge of the transmission case above the 2-6 steel plate as shown in figure 367. Then, measure the length of the rod from the bottom of the “H” Gauge cross bar to the end of . The first spec is clutch disc diameter, taken by simply measuring across the face of the clutch disc. Knowing your pressure plate diameter is valuable too, and you take that measurement from the backside of the pressure plate assembly. Be sure to compare those measurements against the clutch you’re ordering. In Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 millimetres is classified as metal foil. The thickness of metal foil, sheet, and plate is measured in millimetres, mils, and gauges. Shims are thin washers that adjust the distance between the clutch plate and the pulley. Select the appropriate thickness of shims from your kit. It’s often best to start with a thinner shim and add more if necessary. Place the shims onto the shaft where the clutch plate was mounted. Step 6: Reinstall the Clutch Plate. Reattach the clutch .

While inspecting the clutch plate, also check the clutch release bearing. It should move smoothly and not make any unusual noises. Step 5: Measure the Clutch Plate Thickness. Use a caliper to measure the thickness of the clutch plate. Refer to your vehicle’s service manual for the specified thickness range.It features a clutch plate pack that is premeasured and has the correct shims, which takes the measuring and guesswork out of the process. I highly recommend purchasing this new clutch plate kit for your performance rebuild. . They must be kept together to ensure the correct clutch plate stack thickness. Soak the plates in a container. Step 3 . When installing the clutch packs in a 4l60e and measuring clearances, is it a good idea to: 1. first install them dry and take clearance reading and then remove, soak, and reinstal, or . and different thickness apply plates and backing plates to get your clearances where you want them to be. The thinner steels are a lot cheaper than the apply .

Clutch Pack Thickness. A typical dirt bike clutch pack is made up of driven (metal) and drive (paper or cork on metal) plates. If the overall thickness of the pack becomes too thin as a result of wear on those drive/driven plates, the clutch will slip and need replacing. Your machine-specific owners manual will state the minimum thickness for .

how to test arm torsion strength

WEBAs melhores marcas em moda country masculina é na Rodeo West. Itens na sacola 0 . Produto . Subtotal . Consultar frete . Total . R$ 0,00 . O CARRINHO DE COMPRAS .

how to measure clutch plate thickness|how to measure clutch height